How To Repair Top Flush Parts

Easy Fixes for Common Toilet Tank Parts

Learn how to set up broken parts of your toilet such equally flappers, fill valves, affluent valves and handles.

![]() Time

Time

An hr or less

![]() Complexity

Complexity

Beginner

![]() Toll

Toll

Less than $xx

Introduction

Toilets have moving parts, and moving parts vesture out or intermission. If your toilet won't stop running, try repairing or replacing these key toilet parts. Nosotros cut away the fronts and backs of new toilets to show you lot how to replace these toilet tank parts. Your toilet and toilet tank parts won't look then pristine inside. You'll observe scummy surfaces, water stains and corrosion. Just don't exist squeamish — the water is every bit clean every bit the stuff that comes out of your faucets.

Tools Required

Materials Required

- Fill valve

- Flapper

- Toilet handle and retaining nut

- Valve washer

Finding the Problem is Normally Simple

A toilet runs constantly considering the fill valve that lets water into the toilet tank isn't closing completely. A toilet runs intermittently because the flapper valve opens slightly for a few minutes. In either case, you lot have to figure out why that toilet fill valve isn't stopping the incoming water flow and if in that location are broken toilet parts that need attention.

To ready toilet issues, you lot first need to know how a toilet works. Spotter this video to learn just that.

Project step-by-step (19)

Step 1

Look for Leaks

- If you find leaks coming from the tank bolts or toilet affluent valve, you lot'll nearly likely need to remove the toilet tank from the bowl and then you can supercede the tank bolts, the rubber washers and the gaskets on the flush valve.

- If at that place are leaks around the fill valve, tighten the locknut.

- Leaks can come up from cracks in the tank, too. In that case, the just reliable solution is a new toilet.

Stride 2

If You Don't Find Leaks, Lift Off the Tank Cover

There are really only 2 master toilet tank parts: The toilet flush valve, which lets h2o gush into the bowl during the flush, and the fill valve, which lets water refill the tank later the affluent. When a toilet runs constantly or intermittently, one of these valves is usually at fault.

- Look at the overflow tube to decide which toilet valve is causing the trouble.

- If water is inundation into the tube, there's a trouble with the toilet fill valve.

- If the h2o level is below the tiptop of the tube, the affluent valve is leaking, letting water trickle into the bowl. That slow, constant outflow of h2o prevents the fill valve from closing completely.

Step three

Accommodate the Float

If your flapper valve has a brawl that floats at the end of a rod, gently elevator the rod and mind. If the water shuts off, you lot may be able to stop the running by adjusting the float.

- Gently bend the bladder arm downwardly to put extra pressure on the toilet valve.

- To suit a float that doesn't accept an arm, see Step 14 "Adapt the Float" beneath

- Flush the toilet to come across if it works.

- Some fill toilet valves accept a float adjustment screw on height (come across beneath). If there is no adjustment spiral, bend the float arm. If you accept a Fluidmaster-style fill valve, make sure it'southward adjusted properly (Photo viii). Yous don't take to empty the tank to brand these adjustments.

Pace 4

Accept Off the Make full Valve Cap

- Remove the fill valve cap.

- On this type of toilet valve, press downwards and turn counterclockwise. Remove screws on other types of valves.

Step 5

Affluent the Valve with Water

- Cover the flapper valve with your hand.

- Turn on the water (cautiously, then you don't get sprayed!) and let it flush out the toilet valve for a few seconds.

Step vi

Replace the Washer

- Inspect the washer for wear or cracks when yous remove the cap to affluent out the valve.

- Supercede a worn, croaky valve washer past prying the old washer out of the cap with a modest screwdriver.

- Press the new one into place.

- Replacing a bad washer is cheap and like shooting fish in a barrel. Just finding the right washer may non be. The nearly mutual washers are often available at habitation centers and hardware stores.

- Pro tip: Professional plumbers usually replace the whole make full valve rather than hunt for a replacement washer.

- Replacing a bad washer is cheap and like shooting fish in a barrel. Just finding the right washer may non be. The nearly mutual washers are often available at habitation centers and hardware stores.

If these fill valve repairs don't work, supplant it.

Step vii

To Replace the Make full Valve, Start past Removing the Water from the Tank

- Turn off the water at the shutoff valve.

- Flush the toilet and hold the flush valve open up to drain the tank.

- Sponge out the remaining water or vacuum it up with a wet/dry out vacuum.

- If you don't accept a shutoff, turn off the water supply at the main shutoff valve, where water enters your dwelling house. This is a good fourth dimension to add a shutoff valve side by side to the toilet or supervene upon i that leaks. This is also a skillful time to replace the supply line that feeds your toilet.

Step 8

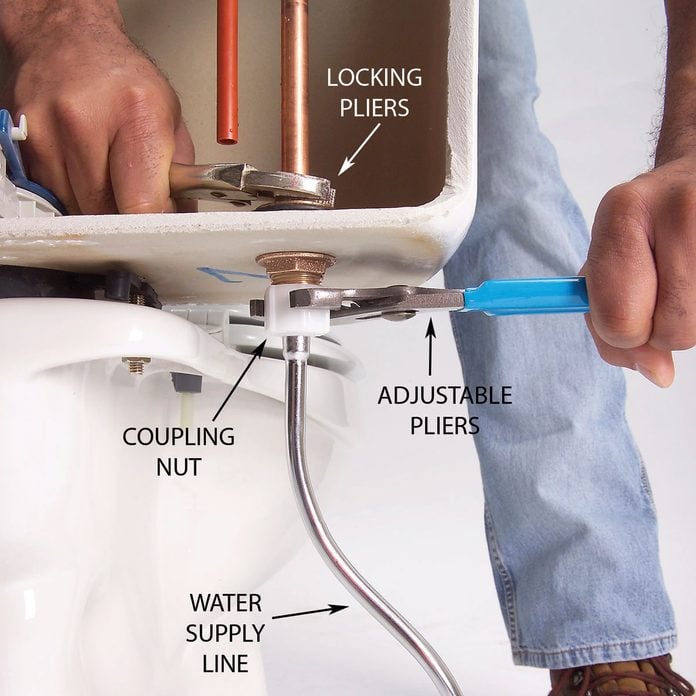

Remove the Coupling Nut

- Unscrew the coupling nut that connects the supply line.

- If the toilet valve turns inside the toilet tank, agree its base of operations with a locking pliers.

- Pro tip: Throw a towel on the floor underneath to catch water that will drain from the line.

Stride 9

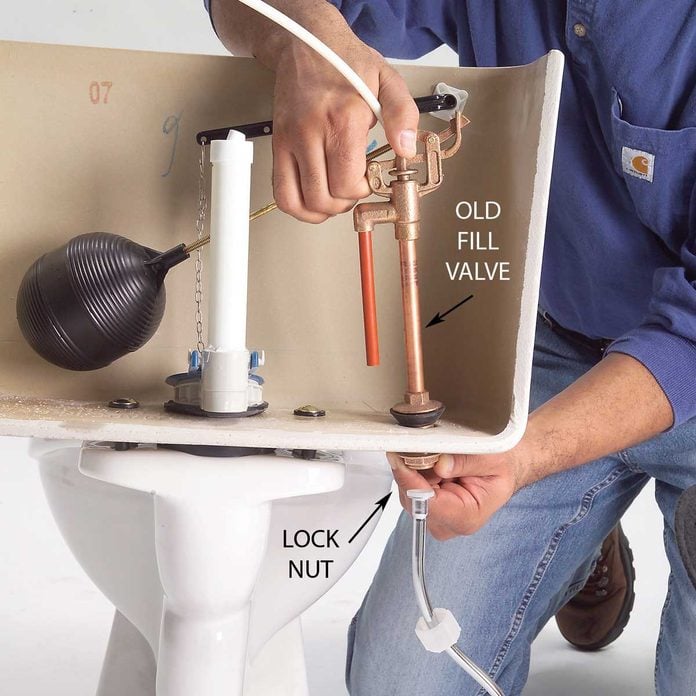

Remove the Old Flapper Valve

- Remove the locknut that holds the toilet valve to the tank.

- Push downwardly gently on the valve as you unscrew the nut.

- Pull out the old valve.

Step 10

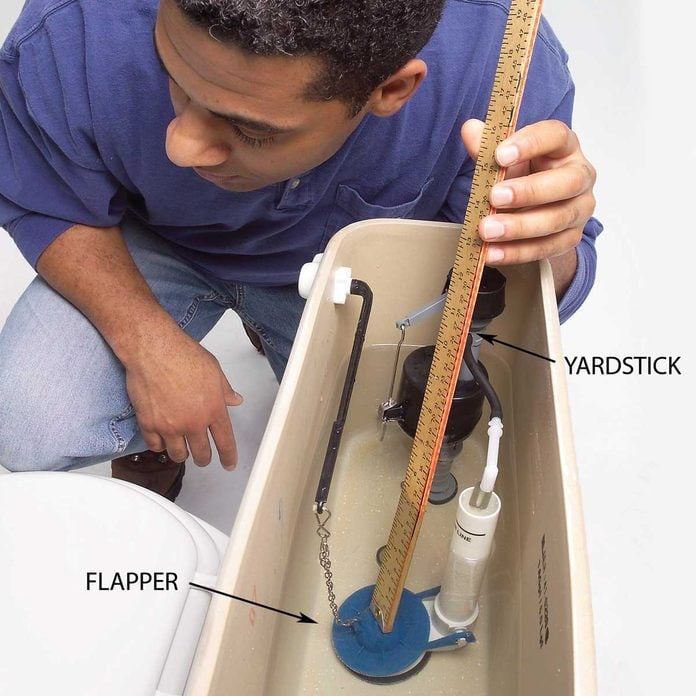

Mensurate the Overflow Tube

- Measure the height of the overflow tube.

- Measure to the superlative of the tube, non to any water level label on the tube.

Footstep 11

Twist the Top of the New Valve to Adjust the Height

- Adapt the height of the new fill valve by holding the base and twisting the top.

- The height from the base of operations to the CL (disquisitional level) mark should be the height of the overflow tube plus 1 inch.

Stride 12

Install the New Fill Valve

- Remove the cap, printing downwardly to compress the washer and screw on the locknut.

- Connect the supply line and affluent the valve.

- Reset the cap and check for leaks.

Step 13

Cut the Fill up Tube to Fit the Angle Adapter

- Slip the fill tube onto the fill up valve.

- Prune the angle adapter onto the overflow tube.

- And so cut the tube to fit and slip it onto the bending adapter.

Step 14

Conform the Float

- Turn on the water to fill up the toilet tank.

- Pinch the spring clip and slide the bladder upwards or down to set the water level one inch below the elevation of the overflow tube or to the water line marked on the tank.

- When you turn the water supply dorsum on, immediately check for leaks and tighten the nuts more than if necessary.

Stride 15

To Fix the Flush Valve, Showtime past Listening for Running Water

- Push down on the flapper with a yardstick and mind.

- If the sound of running water stops, the flapper needs replacing.

- If extra pressure level on the flapper doesn't stop the running noise, water is probable escaping through a cracked or corroded overflow tube. In that example, y'all have to disassemble the tank from the bowl and replace the whole flush valve.

- Since the overflow tube is rarely the crusade of a running toilet, we won't cover that repair here.

- If extra pressure level on the flapper doesn't stop the running noise, water is probable escaping through a cracked or corroded overflow tube. In that example, y'all have to disassemble the tank from the bowl and replace the whole flush valve.

Step 16

Clean the Flapper

- Plough off the water.

- Flush the toilet to empty the tank and then run your finger around the rim of the flush valve seat.

- If you experience mineral deposits, clean the flush valve seat with an abrasive sponge or Scotch-Brite pad.

- Don't use anything that might roughen it.

- If cleaning the flush valve seat doesn't solve the problem, you need to replace the flapper.

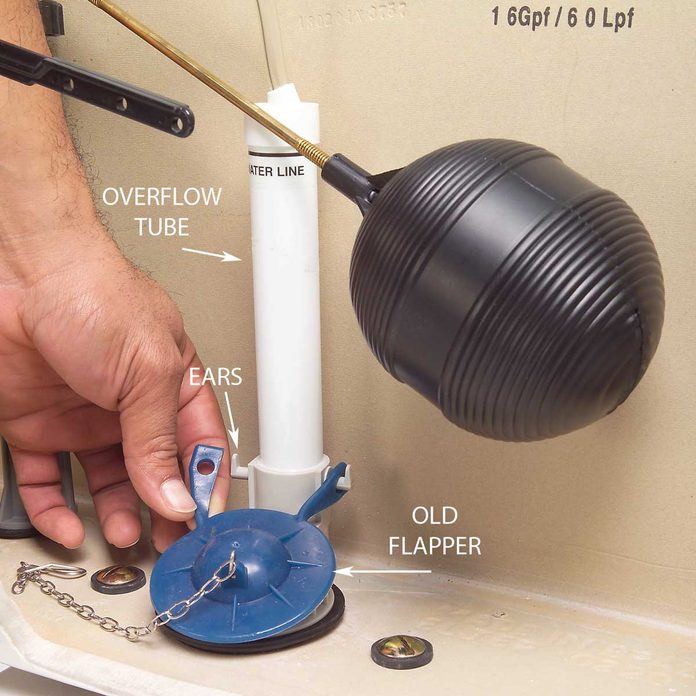

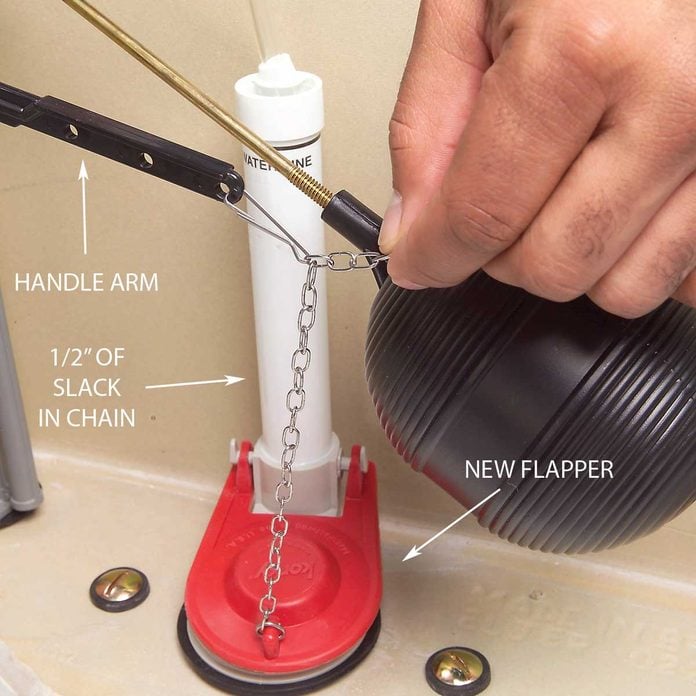

Stride 17

Remove the Flapper

- Remove the old flapper from the ears of the overflow tube and detach the chain from the handle arm.

Stride 18

Install the New Flapper

- Adhere the new flapper to the overflow tube and hook the chain to the handle arm.

- Leave 1/2-in. of slack in the chain.

- If there's too much slack in the concatenation, it tin tangle up and prevent the flapper from closing firmly. A concatenation with as well little slack can cause trouble too.

- Plow the water back on and test flush the toilet.

- Replacing your flapper may require slightly different steps than we show. Your flapper may screw onto a threaded rod or have a band that slips over the overflow tube.

- If you have an unusual flush valve, finding a replacement flapper may be the hardest part of the job.

- Replacing your flapper may require slightly different steps than we show. Your flapper may screw onto a threaded rod or have a band that slips over the overflow tube.

Step 19

Replace a Broken or Corroded Toilet Flush Handle

- Toilet affluent handles are another office of a toilet that can cause toilets to keep running.

- Often handles are toilet parts that get loose or corroded and no longer pull the flap up or drop it dorsum down properly.

- Information technology's an easy repair, but there's a fob to getting the flush handle out.

- Often handles are toilet parts that get loose or corroded and no longer pull the flap up or drop it dorsum down properly.

- The retaining nut inside the tank is a contrary thread. So if you're in forepart of the toilet, turn the nut to the left to loosen.

- Then remove the one-time handle and lever, slide the new handle into place, and thread on the retaining nut.

- Tighten by turning to the correct.

Originally Published: November 28, 2022

How To Repair Top Flush Parts,

Source: https://www.familyhandyman.com/project/parts-of-a-toilet/

Posted by: charlandabligaverins.blogspot.com

0 Response to "How To Repair Top Flush Parts"

Post a Comment